PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Stainless steel angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves. Stainless steel angle steel is a carbon structural steel for construction. It is a simple section steel, mainly used for metal components and plant frames. In use, it requires good weldability, plastic deformation performance and certain mechanical strength. The raw material billet for the production of stainless steel angle steel is low-carbon square billet, and the finished stainless steel angle steel is delivered in hot-rolled forming, normalizing or hot-rolled state.

Stainless Steel Unequal Angle Steel

Stainless steel angle steel is mainly divided into two types: equilateral stainless steel angle steel and unequal stainless steel angle steel, of which unequal stainless steel angle steel can be divided into unequal equal thickness and unequal thickness. The section height of unequal stainless steel angle steel is calculated by the long side width of unequal stainless steel angle steel.

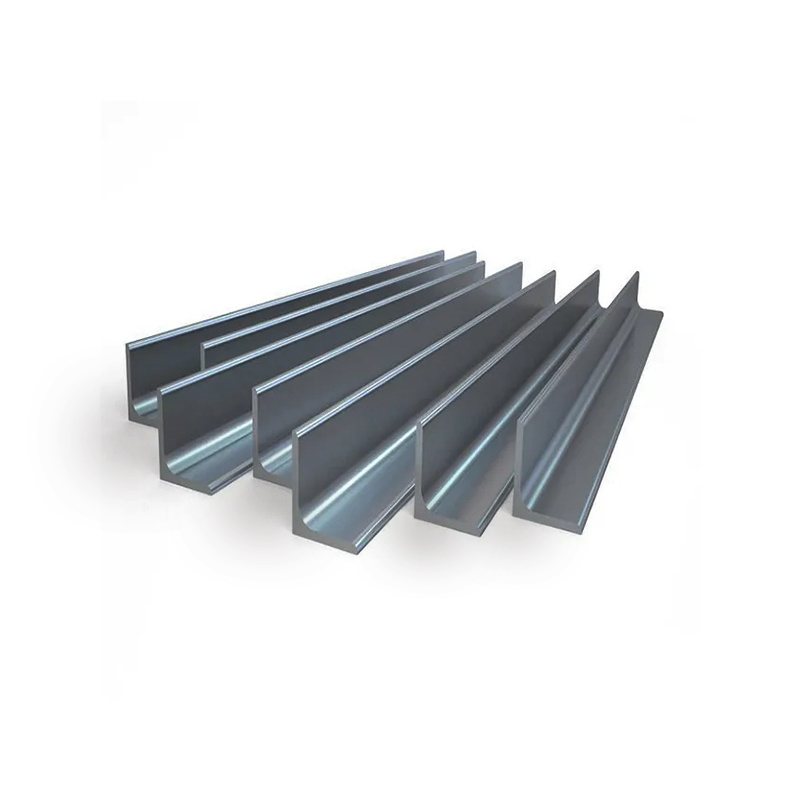

Galvanized Unequal Angle Steel

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold galvanized angle steel. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. The cold galvanized coating mainly ensures the full contact between zinc powder and steel through electrochemical principle, and generates electrode potential difference for anti-corrosion. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. It is to immerse the angle steel after derusting in molten zinc melted at about 500 ℃ to attach a zinc layer to the surface of the angle steel, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs. The cold galvanizing process is used to protect the metal from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the protected surface by any coating method and dried to form a zinc filler coating with a content of zinc in the dried coating (up to 95%). Suitable for repair work (I. e., during repair work, only where the protected steel surface is damaged, the surface can be recoated as long as it is repaired). The cold galvanizing process is used for corrosion protection of various steel products and structures.

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold galvanized angle steel. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. The cold galvanized coating mainly ensures the full contact between zinc powder and steel through electrochemical principle, and generates electrode potential difference for anti-corrosion. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. It is to immerse the angle steel after derusting in molten zinc melted at about 500 ℃ to attach a zinc layer to the surface of the angle steel, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs. The cold galvanizing process is used to protect the metal from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the protected surface by any coating method and dried to form a zinc filler coating with a content of zinc in the dried coating (up to 95%). Suitable for repair work (I. e., during repair work, only where the protected steel surface is damaged, the surface can be recoated as long as it is repaired). The cold galvanizing process is used for corrosion protection of various steel products and structures.

Angle steel, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other. Angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, bus support installation, and warehouse shelves. Angle steel is carbon structural steel for construction, is a simple section of steel, mainly used for metal components and the framework of the plant. In use, it is required to have good weldability, plastic deformation performance and mechanical strength.

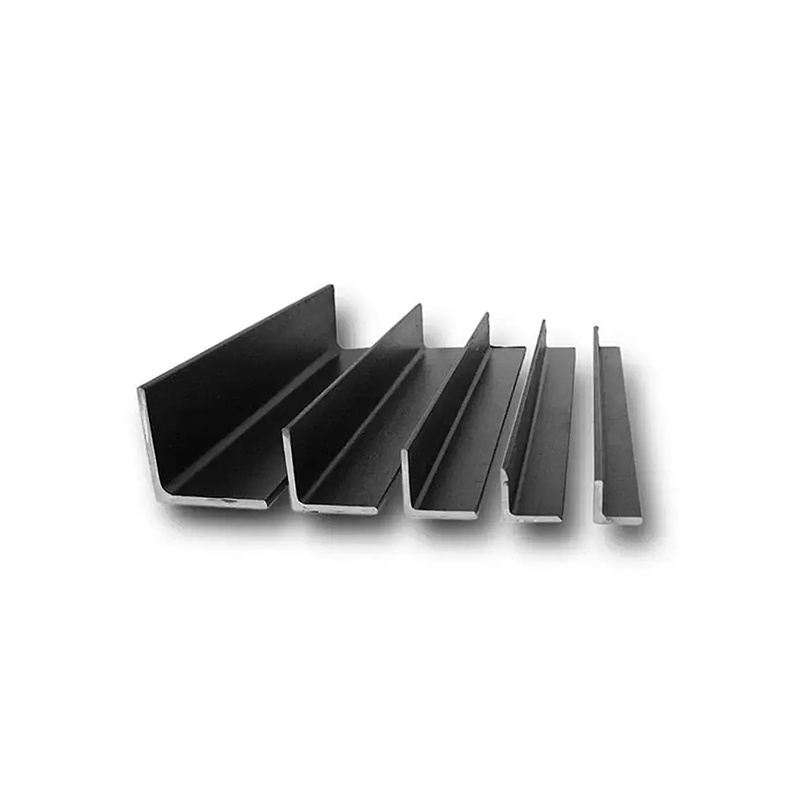

Carbon Steel Unequal Angle Steel

Unequal angle steel is widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses.