EN8/EN9 En Series Carbon Steel Bar

Classification :

PRODUCT DETAILS

EN8/EN9 En Series Carbon Steel Bar Description

En-8 (1040) It is an unalloyed medium carbon steel with reasonable tensile strength. It is usually supplied in a cold drawn or rolled state. Tensile properties may vary, but are usually between 500 - 800 N/mm. It is widely used in applications that require better performance than mild steel but cannot justify the cost of alloy steel. EN8 can be flame or induction hardened to produce good surface hardness and moderate wear resistance.

Product Parameters

|

Product Name |

EN8/EN9 En Series Carbon Steel Bar | |||

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. |

|||

|

Common Round Bar Specifications |

3.0-50.8 mm, Over 50.8-300mm |

|||

|

Flat Steel Common Specifications |

6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm |

|||

|

Hexagon Bar Common Specifications |

AF5.8mm-17mm |

|||

|

Square Bar Common Specifications |

AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm |

|||

|

Length |

1-6meters, Size Accept Custom |

|||

|

Diameter(mm) |

Hot Rolling Round Bar |

25-600 |

Cold Rolling Square Bar |

6-50.8 |

|

Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

|

Cold Rolling Round bar |

6-101.6 |

Forged Rebar |

200-1000 |

|

|

Surface Process |

Bright, Polished, Black |

|||

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|||

Chemical Composition

|

Grade |

C% |

You are% |

Mn% |

Cr% |

Mo% |

W % |

|

EN-1A |

0.007-0.15 |

0.10 |

0.80-1.00 |

S |

P |

- |

|

0.20-0.30 |

0.70 MAX |

|||||

|

EN-8 |

0.35-0.45 |

0.05-0.30 |

0.60-1.00 |

S |

P |

- |

|

0.06 MAX |

0.06 MAX |

|||||

|

EN-9 |

0.50-0.60 |

0.05-0.30 |

0.5-0.80 |

- |

- |

- |

|

EN-19(V 320) |

0.35-0.45 |

0.10-0.30 |

0.5-0.80 |

0.90-1.40 |

0.20-0.40 |

|

|

EN-24(V 130) |

0.35-0.45 |

0.10-0.35 |

0.45-0.70 |

0.90-1.40 |

0.20-0.35 |

NI |

|

1.3-1.8 |

||||||

|

EN-31 R-100 |

0.90-1.20 |

0.10-0.35 |

0.30-0.75 |

1.00-1.60 |

- |

- |

|

EN-36C E-200 |

0.12-0.18 |

0.10-0.35 |

0.30-0.60 |

0.60-1.10 |

- |

NI |

|

3.0-3.75 |

||||||

|

EN-42 |

0.70-0.85 |

0.10-0.40 |

0.55-0.75 |

- |

- |

- |

|

EN-44 |

0.90-1.20 |

0.30 |

0.45-0.70 |

- |

- |

- |

|

EN-45 F-110 |

50-0.60 |

1.5-2.0 |

0.70-1.00 |

- |

- |

- |

|

EN-351 |

0.10-0.20 |

0.35 |

0.60-1.00 |

0.40-0.80 |

0.08-0.10 |

NI |

|

0.60-1.00 |

||||||

|

EN-353 |

0.10-0.20 |

0.35 |

0.50-1.00 |

0.75-1.25 |

0.08-o.15 |

NI |

|

1.00-1.50 |

Mechanical Properties

|

Grade |

Hardening Temperature |

Quenching Medium |

Tempering Temperature |

Brinell Hardness |

JapanHe |

AISI |

|

EN-1A |

- |

- |

- |

- |

- |

- |

|

EN-8 |

750-900 |

OIL |

150-200 |

|

- |

1040 |

|

EN-9 |

850-900 |

OIL |

200-250 |

55-60 |

- |

- |

|

EN-19 (V 320) |

900-950 |

OIL |

200-225 |

45-55 |

SCM 4 |

4140 |

|

EN-24 (V 130) |

830-860 |

OIL |

540-680 |

45-55 |

SNCM 8 |

4340 |

|

EN-31 R-100 |

820-860 |

OIL |

180-225 |

59-65 |

- |

- |

|

EN-36C |

780-860 |

OIL |

170-210 |

61-63 |

SNC 22 |

3415 |

|

EN-42 |

600-700 |

DIRECT HARDENING |

|

40-45 |

- |

- |

|

EN-44 |

650-750 |

OIL |

150 |

45-50 |

- |

- |

|

EN-45 |

830-860 |

OIL |

470-520 |

50-55 |

- |

9255 |

|

EN-351 |

850-860 |

OIL |

175-200 |

62-64 |

- |

- |

|

EN-353 |

840-870 |

OIL |

150-200 |

62-64 |

- |

- |

Scope of Application

The EN series is widely used in many general engineering applications. Typical applications include shafts, studs, bolts, connecting rods, screws, etc.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

Packing and delivery

We are a professional steel production and sales company. It has convenient logistics and exports, excellent production and operating environment, mature industrial facilities and complete related support industries. Our traditional advantages are complete varieties, sufficient inventory, good inventory, low price, short delivery time and good services.

APPLICATION FIELD

FACTORY WORKSHOP

Factory

Factory

Factory

Factory

Factory

Factory

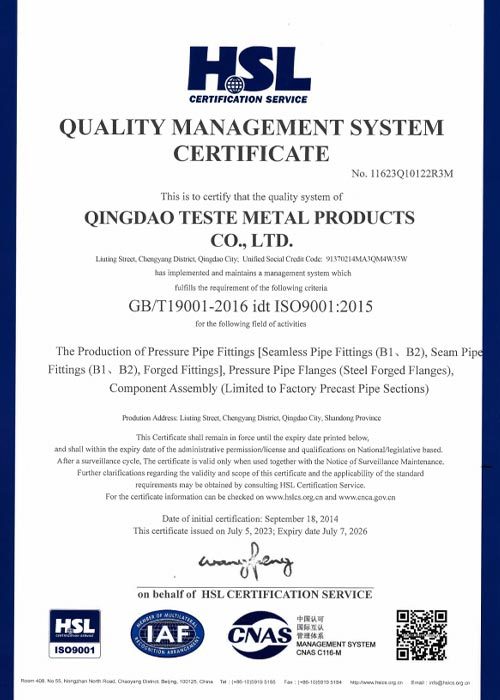

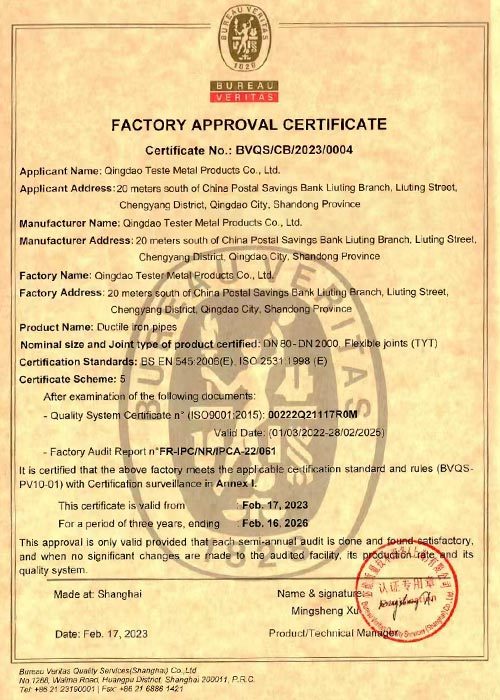

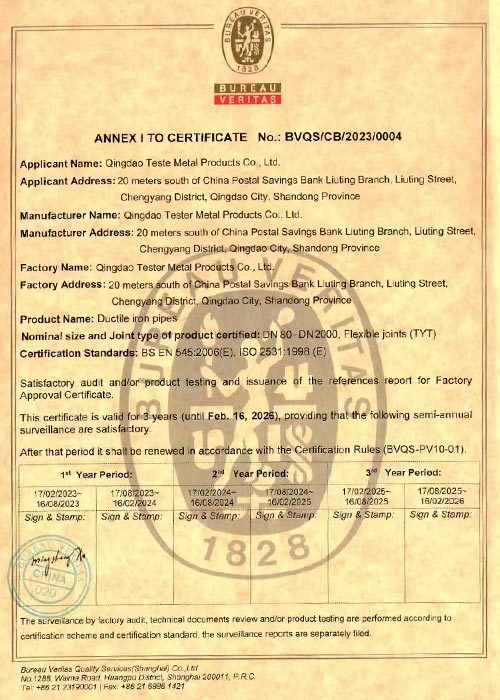

CERTIFICATE

Honor

Honor

Honor

Honor

Honor

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE